Trelleborg will showcase its cutting-edge polymer solutions for aerospace and advanced air mobility (AAM) applications at the Paris Air Show.

With a legacy that dates back to the 1950s, Trelleborg has continually led the way in hydraulic systems for aircraft, cementing its position as a key player in the aerospace industry. This year’s Paris Air Show marks a significant milestone for the company as it expands its commitment to delivering an expanded portfolio of cutting-edge sealing solutions for the aerospace sector.

Trelleborg has recently demonstrated its ambition in the aerospace sector and enhanced its capabilities and products with the acquisition of MG Silikon. Based in Lindau, Germany, it specializes in sealing solutions such as seals for airframes, windows, and cabins. In addition, the upcoming acquisition of 4M, based in Tukwila, Washington, US, will make Trelleborg the largest global supplier of aerospace window seals1.

Torben Andersen, Director Aerospace Segment, says: “The Paris Air Show provides an exceptional platform for us to showcase our expanded range of innovative polymer solutions and demonstrate our expertise in sealing and component technologies to the global aviation community. We are committed to developing sustainable, efficient solutions that support the aviation industry’s transition towards greener transportation.

“We can supply a solution for virtually all aerospace sealing challenges, leveraging the use of polymers and plastic components for lightweight designs that benefit the environment while ensuring improved safety and comfort for passengers. Our portfolio of products and materials is optimized to work in severe weather and extreme temperatures, provides outstanding resistance to harsh chemicals such as de-icing fluids, and can be fitted to any type of aircraft or AAM vehicle.”

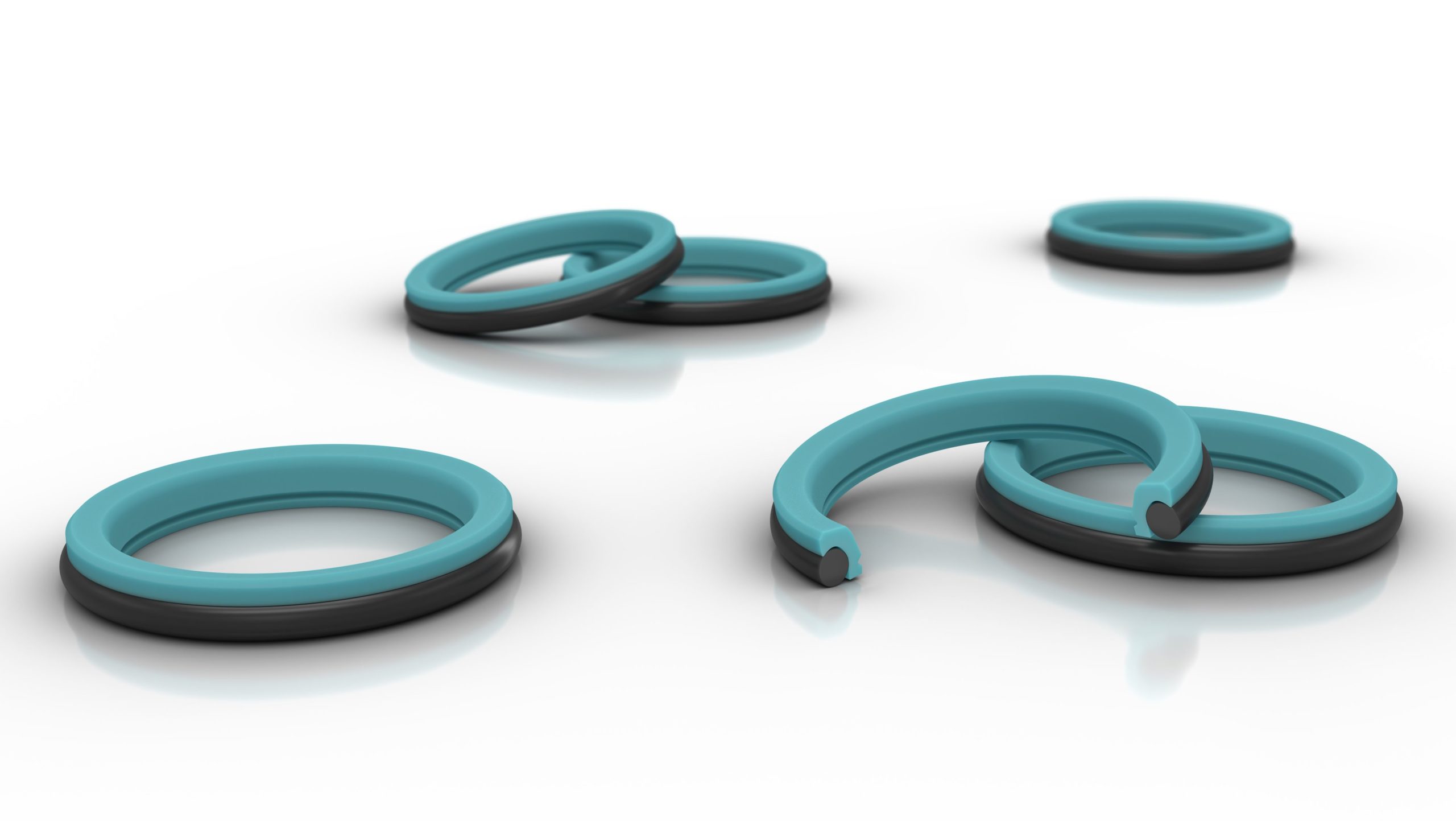

In Paris Trelleborg will feature the Turcon® VL Seal® II for hydraulic sealing of actuators in flight controls and landing gear, and seals in landing gear shock absorbers. Based on the groundbreaking and well-proven Turcon® VL Seal®, this second-generation seal offers enhanced sealing efficiency, easier installation, and even greater reliability. Extensive testing proves its outstanding ‘zero’ leakage performance, which extends service life and minimizes planned maintenance.

During the five-day event, attendees can learn about Trelleborg’s specialist sealing technologies for cabins and interiors, airframes and structures, energy management systems, propulsion, controls and actuation, with technical experts on hand to discuss individual application requirements.

Trelleborg manufactures a range of components for functional and aesthetic interior aerospace applications such as storage bins, light fittings, and air conditioning nozzles and bezels. Materials are approved to all international smoke and toxicity standards and available in a range of standard and custom profiles. FDA- and NSF61-approved O-Rings are suitable for applications where seals come into contact with food or drinking water. Advanced extrusion technology is utilized for seat tracks, rub strips and gap seals, with materials color-matched to cabin interiors.

Trelleborg’s airframe seals are typically used for aerodynamic sealing of doors, windows, canopies, hatches, and panels. Seals are reinforced to provide the load, deformation and wear properties required for variable working conditions in both static and semi-static applications. They offer low friction, good abrasion resistance, high flexibility and long life, and can be combined with composite or metal structures to limit part count and ease installation.

To support the reliable function of high-performance electrical systems in AAM vehicles, Trelleborg has engineered solutions that provide an electromagnetic shield, spark resistance and protection from multiple environmental factors. In addition, custom sealing solutions for high-voltage batteries allow for inexpensive, fully automated assembly and simplified disassembly if the battery requires maintenance. Trelleborg’s thermal management seals prevent bleed air from escaping the ducts used in numerous applications, such as bleed valves, anti-icing systems, and air conditioning systems.