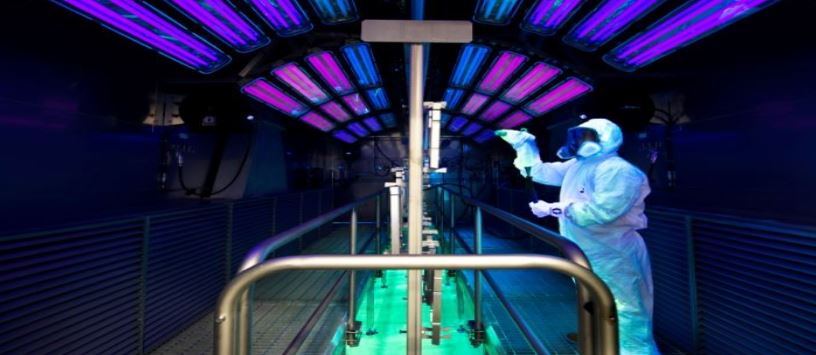

In order to reduce complexity, costs and efforts for TRM testing, Rohde & Schwarz concentrates on test and measurement solutions to maximize the performance of AESA designs with highest precision instruments and automation of complex test scenarios.

Modern active electronically scanned array (AESA) radars are a strong focal point of the global aerospace and defense industry. The performance of state-of-the-art AESA radar systems depends strongly on the performance of the individual transmit-receive-module (TRM) assembled in the antenna array. Rohde & Schwarz offers new test and measurement solutions for TRM performance validation, enabling the customer to maximize their radar system capabilities.

Typical TRM test cases can be covered with a single Rohde & Schwarz network analyzer as a turnkey solution, such as the R&S ZNA. If higher performance such as the pulsed noise figure is required, the R&S FSW signal and spectrum analyzer is added to the setup. When combined with the integrated calibration routine, this simplifies the setup, ensuring full accuracy and high repeatability. Users benefit from reduced test procedure complexity and a minimized cabling assembly.

The R&S TS6 TRM test library optimizes Rohde & Schwarz test equipment for top speeds, in combination with fast control handover. Due to fast frequency sweeps and multiple measurements within one pulse, the number of required TRM state changes is reduced and overall test time minimized. With the R&S ZVAXTRM signal conditioning unit, all tests run automatically without interaction, including port multiplexing.

The calibration routine in the R&S TS6 TRM test library is a special feature. It collects all the calibration requirements from the test and runs an optimized precise calibration. The support of multiport calibration units enables the efficient calibration of devices under test (DUTs) with many ports. This combination of a simplified test setup with a high degree of automation ensures reliable and reproducible measurements by a scalable solution. It offers a variety of use cases, from manual testing of components to complete module characterization in development and to automated production testing.